Special optical fiber

Face the core pain point: the dilemma of traditional optical fiber in extreme environments

In many cutting-edge technologies and industrial scenarios, environmental factors have become a key bottleneck restricting fiber performance:

High-temperature environment

For example, in aerospace engine monitoring, geothermal detection, or metallurgical process control, continuous high temperatures of hundreds of degrees will cause the aging and decomposition of ordinary optical fiber coatings. and change the core structure, resulting in a surge in signal loss and complete interruption of transmission.

Strong radiation environment

In nuclear power plant reactor monitoring, space satellite communication, and high-energy physics experimental equipment, the continuous bombardment of high-energy particles (such as γ rays and neutrons) will produce defects such as color centers in optical fiber materials, causing a "darkening" effect, causing the optical fiber transmittance to drop off a cliff and greatly shorten the life. Strong electromagnetic interference and complex stress environment

In power substations, near large electrical equipment, or in scenarios such as deep-sea high voltage and oil well exploration, multiple factors, such as strong electromagnetic noise, continuous mechanical vibration, high voltage, and chemical corrosion, are intertwined. Posing a multi-dimensional threat to the physical integrity and signal purity of optical fibers. These pain points not only affect the real-time and accuracy of data but may also directly lead to the failure of critical systems, causing huge security risks and economic losses. Therefore, the development of special optical fibers that can stably adapt to extreme environments has become an urgent need in related industries.

Hirundo Solution: Escort the whole process from customization to validation. Hirundo believes that there is no "one-size-fits-all" fiber, only the "most suitable" solution. We move away from one-size-fits-all standard product thinking and provide end-to-end specialty fiber customization services from in-depth requirements analysis to final environmental validation.

- 1. Deep collaboration and precise definition of requirements

Our team of technical experts will work closely with you to understand your specific application scenario and environmental parameters (e.g., temperature range, radiation dose spectrum, stress type, etc.) and performance metrics (bandwidth, loss thresholds, mechanical strength, etc.). This stage is fundamental to ensure the success of the solution.

2. Customization of special materials and structures

For high-temperature scenarios, we use high-temperature-resistant specialty polymer coatings or even metal coatings instead of conventional acrylate coatings, and use doped optimized quartz substrates to ensure structurally stable and low-loss operation of fibers in extreme temperatures.In order to cope with strong radiation, we have developed irradiation-resistant fiber core materials. which greatly suppress radiation-induced losses and maintain long-term optical performance through selected doping elements (such as radiation-resistant cerium elements, etc.) and unique process treatment.

3. Multi-parameter collaborative optimization design

While meeting environmental tolerance, we use an advanced simulation design platform to synergistically optimize key optical and geometric parameters, such as optical fiber dispersion characteristics, mode field diameter, bending loss, and cut-off wavelength. For example, design low-loss, large-effective area single-mode fiber for long-distance sensing; design special-structure optical fibers that suppress nonlinear effects for high-power transmission; Design the ultimate bend-resistant fiber for cabling in compact spaces.

4. Reliability verification in extreme environments

Each custom fiber must be tested in Hirundo's advanced extreme environment simulation chamber. We simulate real-world operating conditions and conduct long-term high-temperature cycling tests and irradiation-accelerated aging tests for specific energy spectrums. and mechanical reliability tests such as vibration, shock, and tensile forces, and provide detailed performance degradation data reports. Only products that pass the full set of validation schemes will be delivered to customers.

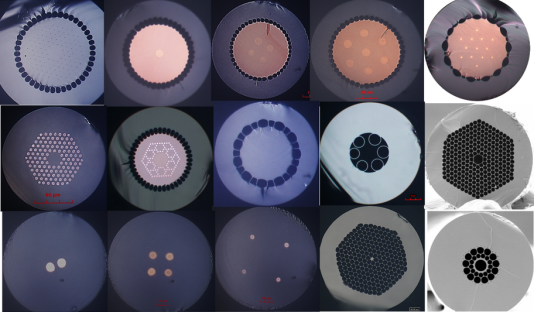

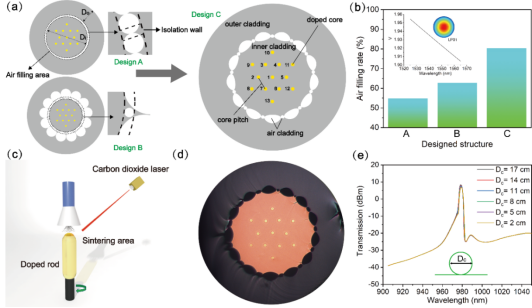

Design and preparation of 13-core erbium-ytterbium co-doped microstructured optical fiber

Core platform advantages: build a reliable cornerstone with hardcore parameters. Hirundo's specialty fiber optic solutions are built on a strong independent R&D and manufacturing platform.

and their core advantages are reflected in verifiable hard indicators: Stable operation in a wide temperature range Our line of specialty fibers can reliably support a wide temperature range of -40°C to +85°C. and some custom products can withstand sustained high or low temperature shocks in excess of 300°C, ensuring consistent performance in extreme cold or hot industrial areas.

- Excellent resistance to irradiation

Platform standard anti-radiation fibers can withstand γ radiation at cumulative doses of up to 10 kGy (Si) with tightly controlled additional losses. For higher dose requirements, we offer enhanced customized solutions.

- Fast response and flexible customization

With our modular design system and mature process library, we can significantly shorten the customized development cycle and quickly respond to customers' joint requirements for special parameters such as special wavelengths, high intensity, small outer diameters, etc.

- Full-chain technical support

From fiber optic design, preform bar preparation, and wire drawing coating

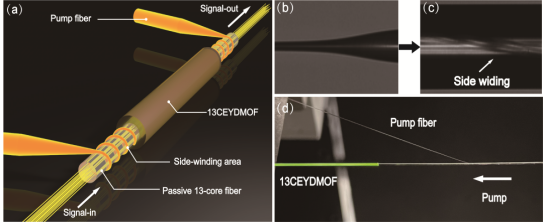

Multi-core fiber side winding combined with cladding pump scheme