Laser Dicing

Laser cutting solution: precise and efficient, complete the complex shape processing of optoelectronic components

Today, as the optoelectronic industry continues to develop towards miniaturization and integration, the shape of components is becoming more and more complex, and the requirements for processing accuracy are becoming more and more stringent. Traditional processing methods are often inadequate in the face of millimeter- or even micron-level special-shaped structures—accuracy is difficult to guarantee, efficiency is low, and yield rate fluctuates, which has become a prominent bottleneck restricting product innovation and mass production. How to achieve high-quality cutting that is both precise and efficient is the core issue that many optoelectronic companies urgently need to solve.

Facing the pain points of the industry: the dual challenges of small precision and complex special-shaped shapes

Optoelectronic components, such as filters, sensor wafers, microlens arrays, optical waveguide devices, etc., usually have the characteristics of special materials, fine structures, and complex shapes. Traditional machining or ordinary laser processing methods often face the following pain points:

Insufficient precision leads to performance failure:

Small chipping, cracks, or enlarged heat-affected zones on the cutting edge can directly alter the physical and optical properties of the component, leading to product failure.

Difficult processing of complex special-shaped structures:

For geometries such as irregular curves, small internal corners, and extremely narrow seam widths, traditional processes have complex programming and poor processing consistency, making it difficult to achieve stable mass production.

Processing efficiency and cost pressure:

High trial and error costs, long processing time of single pieces, and difficulty meeting the needs of rapid market iteration and large-scale delivery restrict the competitiveness of enterprises.

Hirundo Laser Cutting Solutions: Trinity of Precision Empowerment

In response to the above pain points, Hirundo has launched a laser cutting solution that integrates high-precision equipment, intelligent algorithms, and process optimization, aiming to provide customers with full-link support from prototype verification to mass production.

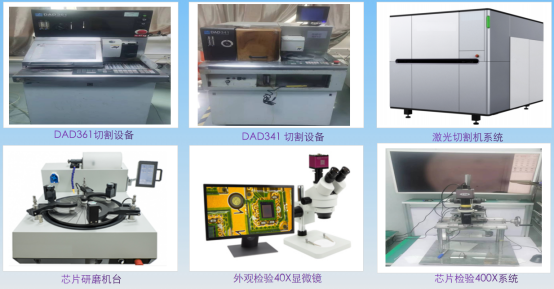

1. High-Power Precision Laser Cutting Equipment: A stable and reliable hardware cornerstone

We use self-developed high-power ultrashort pulse (picosecond/femtosecond) lasers, combined with high-rigidity marble platforms, linear motor drives, and nanoscale grating feedback systems to build ultra-stable processing platforms.

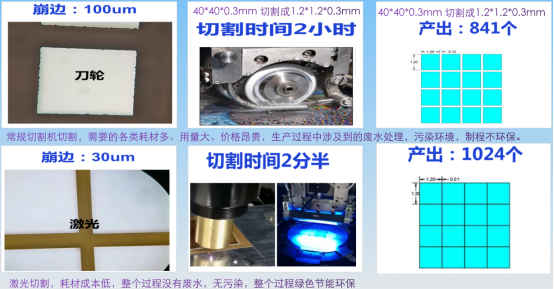

"Cold processing" advantages:

The ultrashort pulse laser greatly reduces the heat-affected zone and achieves near-"cold" cutting, especially suitable for fragile and heat-sensitive optoelectronic materials (such as sapphire, ceramics, special glass, compound semiconductors, etc.), effectively avoiding melting, micro-cracks, and material denaturation.

Superior positioning and motion control:

The linear motor drive ensures smooth movement at high speeds and accelerations, and the nanoscale closed-loop feedback system ensures that the positioning accuracy of the table is stable within ±1 μm for a long time, laying the physical foundation for ultra-high-precision cutting.

Personalized graphic adaptation and intelligent cutting algorithm: software core driven

Hardware is the torso, and software is the brain. At the heart of our solution lies a robust software system:

Intelligent path planning: For complex special-shaped contours, algorithms automatically optimize the cutting path, prioritizing difficult areas such as internal corners and sharp points to ensure contour integrity and dimensional accuracy. For a large number of identical or similar graphics, intelligent layout and path merging can be performed to reduce empty travel and improve efficiency.

Dynamic Focusing and Beam Shaping

Combined with a high-performance dynamic focusing system, it ensures consistent laser focus characteristics across the processing range. The optional beam-shaping module optimizes the laser spot to the most suitable distribution of the current material and shape, further improving the cutting quality and efficiency.

Mass production process optimization: from single-point excellence to global efficiency

We optimize the laser cutting process throughout the entire production process.

Automatic loading and unloading integration

Support seamless docking with robots, AGVs, and other automation equipment to realize automatic loading, positioning, processing, and unloading of wafers and plates; minimize manual intervention; and ensure continuous production stability.

Online monitoring and quality traceability

Integrate a high-resolution CCD vision system to achieve automatic positioning and correction before processing, real-time monitoring during processing, and sampling inspection of key dimensions after processing. All processing data is traceable to support process optimization and quality analysis.

Production Management System (MES) Docking

Processing data and equipment status can be directly uploaded to the customer's MES system to achieve transparency of production progress, equipment efficiency analysis, and preventive maintenance reminders.

The core advantage of the platform: define the profession with data

The core benefits of Hirundo's laser cutting solutions are ultimately reflected in quantifiable, verifiable results:

Significant efficiency increase:

Compared with traditional processing methods, batch processing efficiency is increased by more than 30% on average. Intelligent nesting and high-speed motion control greatly reduce the man-hours of a single piece, and the automated process reduces the assistance time.

Extreme Precision:

The comprehensive cutting accuracy can reach within ±5 μm, the incision is smooth and burr-free, the verticality of the sidewall is excellent, and the heat-affected zone is extremely small, which significantly improves the consistency and reliability of component performance.

High material adaptability:

It is widely suitable for various metals, ceramics, glass, crystals, polymers, and composite materials, especially for handling optoelectronic materials with high hardness, high brittleness, and multi-layer composites.

Lower comprehensive cost:

High yield rate reduces material waste, high efficiency reduces unit labor cost, and automation reduces manual dependence and error, bringing significant comprehensive cost advantages to customers.

Epilogue

In the rapid development of optoelectronic technology, precision manufacturing capabilities are the cornerstone of innovative ideas. Hirundo laser cutting solution is not only a set of equipment but also a systematic empowerment platform that deeply integrates precision engineering, intelligent software, and production management. We are committed to helping customers overcome the difficulties of micromachining complex shapes, embedding precision, efficiency, and reliability into every link of the production process, and jointly promoting optoelectronic components towards a smaller, more integrated, and smarter future.

Choose Hirundo; the cutting possibilities are endless.